Sheet Metal Rolling Service at best price in Chennai ID 19662739797

Carcassonne (/ ˌ k ɑːr k ə ˈ s ɒ n /, US also /-ˈ s ɔː n,-ˈ s oʊ n /, French: ⓘ, locally [kaχkaˈsɔnə]; Occitan: Carcassona [kaɾkaˈsunɔ]; Latin: Carcaso) is a French fortified city in the department of Aude, region of Occitania.It is the prefecture of the department.. Inhabited since the Neolithic, Carcassonne is located in the plain of the Aude between historic trade routes.

Metal Sheet Rolling UK, Ireland Fabricated Products

The expert craftsmen at Max Weiss Company deliver only perfection in angle bending, beam bending (I-beam and wide flange), bulb flat bending, channel bending, tee bending, section rolling, structural rolling, tube rolling, plate rolling and cold-formed extruded aluminum forming. Accuracy is microscopic. Radius is a flawless circle.

Rolling Sheet Metal Work

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled.

Plate and Sheet Metal Rolling Capabilities Custom Metal Fabrication Precision Metal

12 Products Sheet Metal Curvers A Create bends, curves, and circles in sheet metal. Also known as slip rolls, these curvers can form a single curve. The rollers also have wire grooves to shape three sizes of wire. They mount to a table or bench top. Combination Sheet Metal Shears, Benders, and Curvers

Plate Rolls Custom Metal Plate Rolling Houston, TX & Gulf Coast Campo Sheet Metal Works

Slip and plate rolling machines use their long, cylindrical rollers to form sheet metal or metal plates into rolls. Bar and tube rollers use their compact rollers to form straight bar and tube stock into rolls. Bead rollers pass sheet metal between two rolling dies to add ridges, steps, and other profile shapes that strengthen the sheet.

Rolling Sheet Metal Work

1. Material Thickness. Typically speaking, as material thickness increases, you'll need a larger roll shaft diameter for the mill. As an example, Dahlstrom can form material thicknesses ranging from 0.012" to 0.200", using mills with roll shaft diameters that range from 1.500" to 2.563". That being said, if sheet metal parts have few.

Rolling Sheet Metal Work

Nonsparking Ball Peen Hammers. The face and head are made of aluminum-bronze that is Factory Mutual approved, so these tools inhibit sparking, resist corrosion, and are nonmagnetic. Use the domed end of the head for forming soft metal, rounding off edges, and closing rivets. The flat striking face is for driving nails, pins, punches, and chisels.

Metal Sheet Rolling UK, Ireland Fabricated Products

We also offer a little 12 inch long machine with 1 inch diameter rolls from another company for $395. SR-2420: $860. 24" long x 20 gauge capacity, 1:1 gear ratio, the three rolls are 2 inch diameter, wire bending grooves are for 1/4", 5/16", 3/8" diameter rod, shipping weight: 145 Lbs. SR-3622: $940.

Metal Rolling Advanced Sheet Metal & Marine

Rolling is a metalworking process to reduce the thickness of the metal sheet with the help of rollers. The metal sheet is passed through rotating rollers which puts pressure on the sheet. When that pressure becomes too excessive, the metal sheets go into a plastic state and deformation occurs.

Metal Sheet Rolling UK, Ireland Fabricated Products

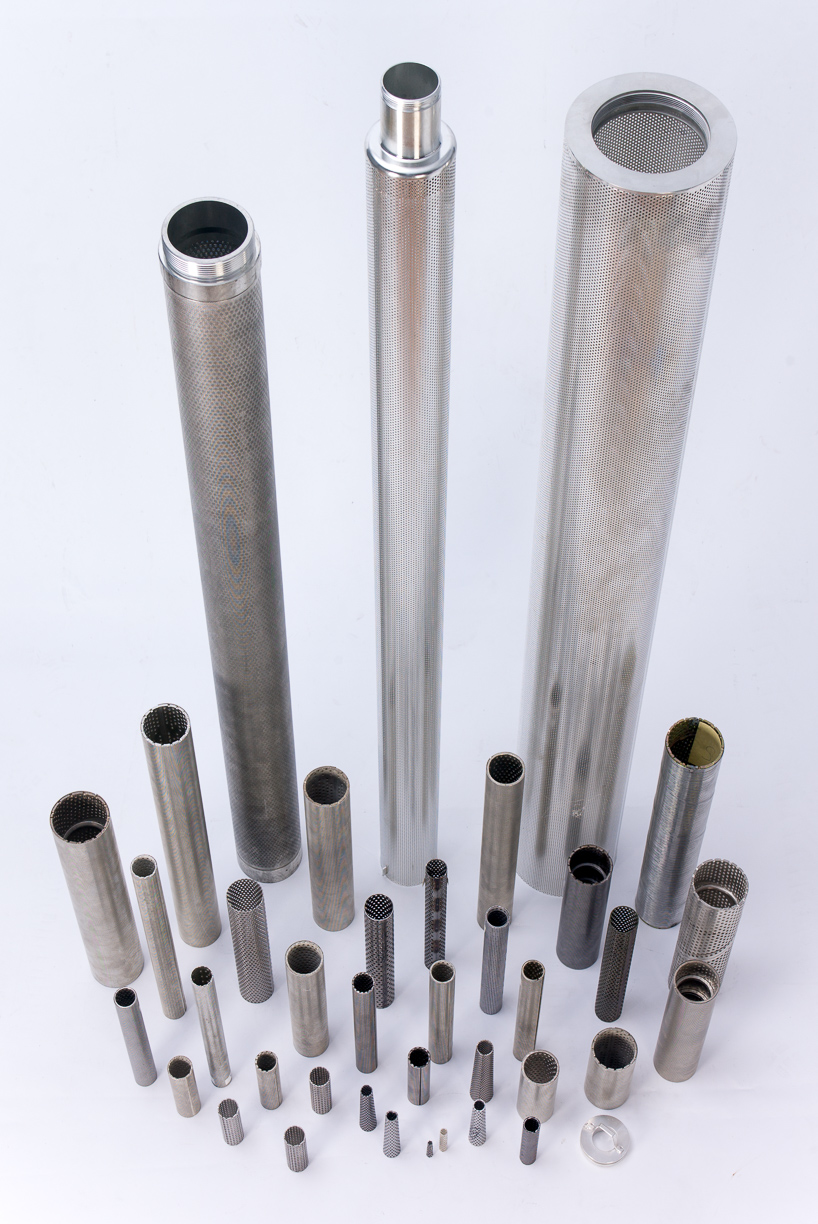

As the name suggests, sheet metal rolling equipment is used for rolling sheets and strips in the metal fabrication industry. These machines come in two roller or three roller designs, depending on how you want to roll, bend, and cut the metal sheet. At Woodward Fab, we provide different types of sheet metal rolling equipment.

Rolling Sheet Metal Work

Rolling a metal above its recrystallization temperature breaks apart the old grain structure and reforms a new one. Grain boundaries are destroyed and new tougher ones are formed, along with a more uniform grain structure. Metal rolling pushes material, closing up vacancies and cavities within the metal.

Sheet Metal Rolling Alumac Industries

(720 - 10 )x 3,1415 = 2 230,47 mm. Note: Often manufacturers prefer to cut the unfolding of thick materials a bit shorter, since the lower edges collide earlier after rolling - pic.4. Furthermore, cutting the unfolding 3-10mm short, provides 1-3mm clearance for welding seam.

Rolling Sheet Metal Work

Edge Cracks. During the rolling process, the sheet metal may come off the machine with cracks along its edges. This defect is called edge cracks and happens when there are high tensile stresses. High tensile stresses occur from uneven heating, uneven rolling, or excess quenching. To avoid this, ensure that the rolling process is adjusted to the.

Sheetmetal Rolling Metro Sheetmetal and Fabrication

The sheet metal rolling process consists of passing metal stock through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. Sheet Metal Forming Between Rolls To determine the designation of sheet vs. plate in general terms we can say that anything 1/8″ and thicker is a plate and anything less than 1/8″ is a sheet.

Rolling Sheet Metal Work

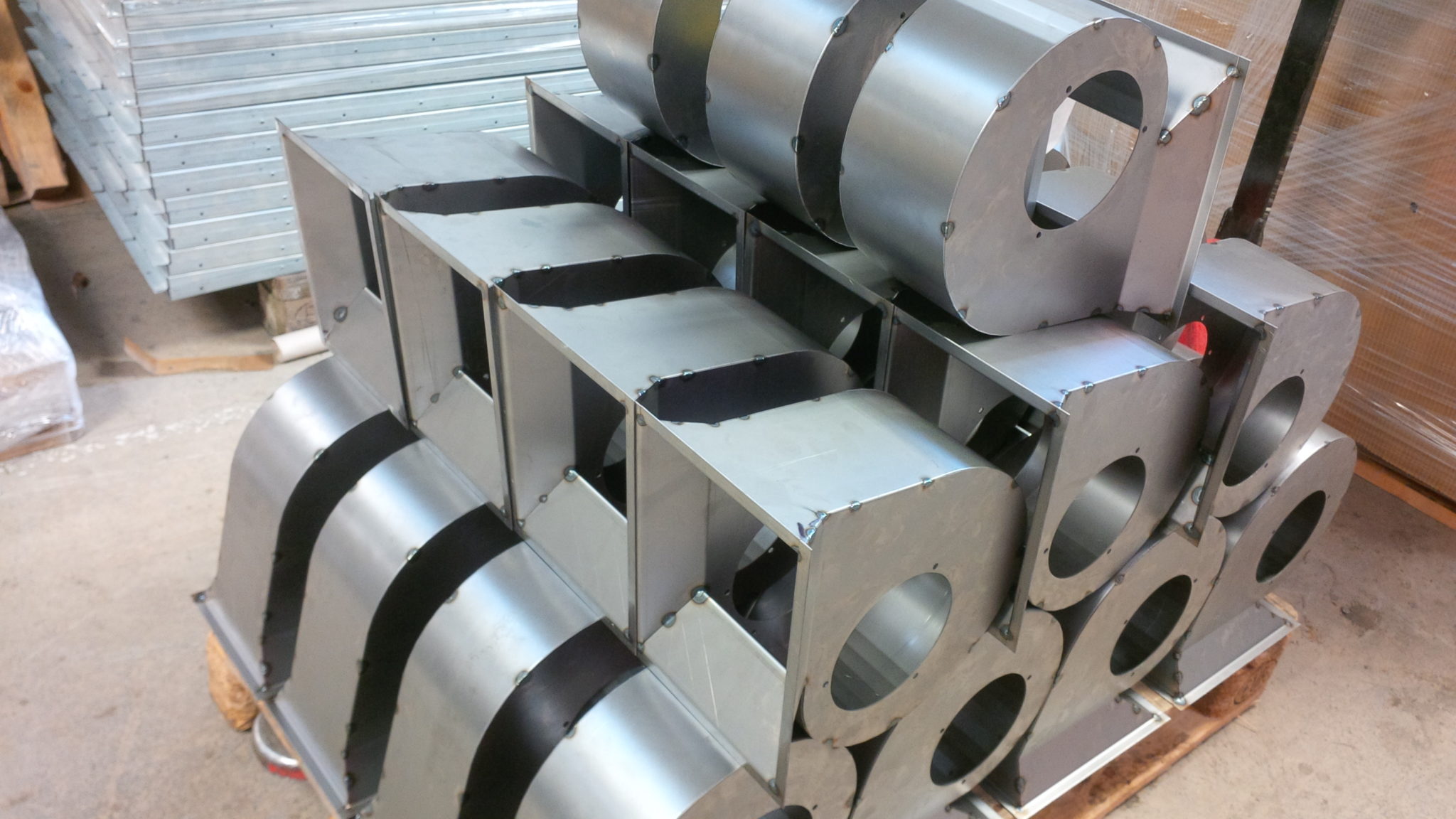

Custom Metal Fabrication Custom Rolling and Bending. We Bend Stainless Steel, Carbon Steel, Aluminum, Brass, Copper, Nickel Alloys, Galvanized Steel and Other Metal. METAL ROLLING AND FORMING SERVICES Pipe Rolling, Tube Rolling

Astron Metal Works Corporation Sheet Metal Rolling

If you wonder how sheet metal forming is different from rolling, read on to find out! The main difference is that while rolling forces the metal to flow into a different shape, sheet metal forming works by causing deformation in the material overall, with minimal effect on the grain structure or the thickness of the material.